We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

500 L. Standard Tank Unit,10µm large filter, 3:1 ratio pump

One of the techniques used to filter the oil is the use of a comprehensive lubricant storage system - Lustor! The bulk system that combines storage, filtration and breather technologies to keep lubricants clean and dry before they enter your equipment. A safe, efficient and convenient method of storing and dispensing lubricants. Lustor systems are an economical way to save space on plant floor, while keeping lubricants organized and contaminant free!

500 L. Standard Tank Unit,10µm large filter, 3:1 ratio pump

The Lustor System was designed to store, clean and dispense lubricants in the workplace in order to keep the lubricants dry and contaminant free, saving time and money. The oil is decanted from the storage drum and stored in the Lustor System. This oil can be recirculated for additional filtering and again the oil is filtered when it is dispensed into an oil container via a flow meter.

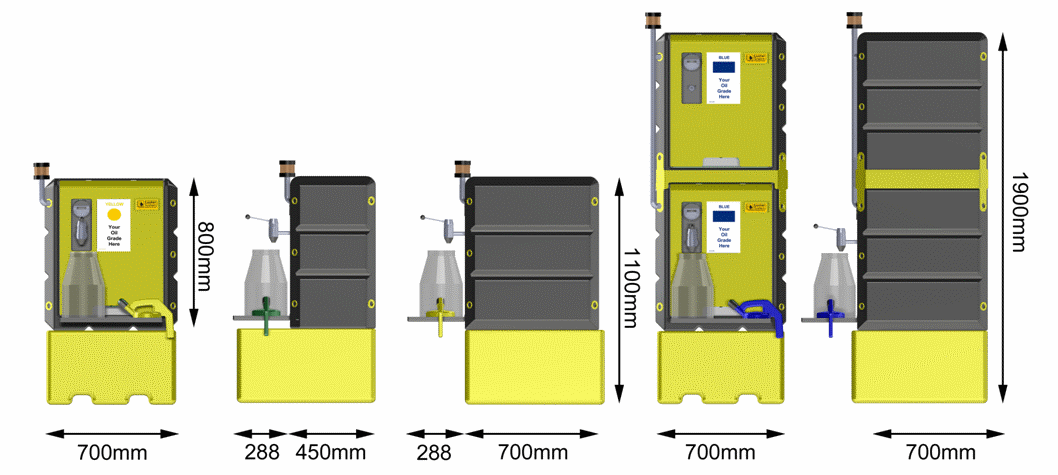

The Lustor System is available in three sizes: 125 litre, 250 litre and 500 litre. The 250 litre can be stacked two high. There is also a Wall Mounted System for use in conjunction with supplier’s drums. Each System can have a lubricant identification label located on the front of the system.

A range of accessories are available which includes underframes, retention tanks (bunds), hose pipes, oil containers, shelves, filter and pump upgrades and cupboards.

The Lustor System conforms to EU Machine Directory 2006/EC EN ISO 12100:2010 and is CE marked and compliant.

|

|

|

|

|

125 LITRE SYSTEMPart # LST-1-70-3-STD125 litre standard tank unit 10 µm large filter 3:1 ratio pump |

250 LITRE SYSTEMPart # LST-2-70-3-STD250 litre standard tank unit 10 µm large filter 3:1 ratio pump |

500 LITRE SYSTEMPart # LST-5-70-3-STD500 litre standard tank unit 10 µm large filter 3:1 ratio pump |

WALL MOUNTED SYSTEMPart # LST-0-70-3-STDWall mounted standard unit 10 µm large filter 3:1 ratio pump |

Basic Components

All individual units are equipped with the Lubrication Reliability™ compliant basic components:

- Heavy duty pneumatic oil pump

- Hydraulic filter with saturation indicator

- Filter cartridges selected for resp. lube type, viscosity and application

- Desiccant protection breather to keep dust and moisture out

- Lube identification label (colour/symbol/type/viscosity)

The system is designed to be user-friendly including features such as 3D oil sight glasses or levels, digital flow meter to keep track of oil consumption and to detect abnormal spills or lubricant use.

Features

- Polypropylene tanks

- Pneumatic pumps (3:1 air/oil pump)

- 3-way filtration (10-micron filter)

- Oil consumption meter

- Auto shut-off ispensing tap

- Oil level indicator

- Desiccant breather

- Drip tray

- Drum transfer hose kit

- Drum adapter kit

System Dimensions

Benefits

- Compact & expandable

- Cost-effective

- Organized & clean workspace

- Increases work environment safety

- Prevents cross-contamination

- Improves lubricant quality

- Lowers lubricant & maintenance costs

- Less equipment downtime

- Increases productivity

- Complies with Lubrication Reliability

Optional Upgrades/Add-ons:

- Custom Fluid ID Label (for front of system)

- 3 or 20-Micron Filter

- Pneumatic 1:5 Pump

- Spill Containment

- Hose reels

Lustor, the proven storage and dispensing benefits you trust in cost-effective, compact and expandable units. The first step to guarantee that clean oil enters your equipment is to filter it to an acceptable level. Lustor systems ensure every liter of oil is protected from on-site environmental conditions.

| Brand | Lustor |

|---|---|

| Weight | 60 Kg / 132.3 lbs |